Clean Oceans International (COI) is a Santa Cruz, California based 501c3 non-profit.

COI’s Vision is a healthy marine environment free of plastic pollution. COI’s Mission is to reduce oceanic plastic pollution through research, innovation, and direct action. Our Goal is to develop financially attractive and environmentally friendly recycling infrastructure at local levels on a global scale. This can be achieved by deploying 100 PPWC systems over the next 5 years. COI embraces core Values that include honesty, integrity, and transparency.

Clean Oceans International Backstory

|

Founder Jim Holm was traveling through the Panama Canal and was shocked at the amount of plastic waste in the water. It was this moment that convinced him that he had to do something.

|

A New Beginning

COI began in 2008 as The Clean Oceans Project and developed systems for locating, collecting and recycling plastic from the ocean with minimal environmental and financial impact. The Clean Oceans Project was unable to raise the funds to execute their plan and the original team disbanded. Clean Oceans International rose from those ashes in 2015 with a new approach, centered around Portable Plastic Waste Conversion (PPWC). Our agenda is to provide a logical approach to reducing plastic.

Research, Innovation, and Direct Action (RID)

Research

COI’s Research component is called "Environmental Plastic Assessment Program" (EPAP). EPAP works with volunteers conducting simple data collection on shorelines and during cleanup events, generating useful information with minimal financial input and creating awareness of plastic pollution through community networking and corporate team building.

Consistent shoreline and environmental monitoring must coincide with abatement measures to assess any changes positive or not. EPAP is simple enough to be done by 1-2 people using inexpensive hand tools.

Innovation

COI’s Innovation component is shrinking Portable Plastic Waste Conversion (PPWC) technology to convert plastic waste into diesel fuel and other products at any location.

Studies began using the Blest BeH, 1-Kg system and commercial chemistry analysis firms in 2010. Energy testing at COI began with the arrival of the initial EFT 100 PPWC system in 2015. In 2020, the COI PPWC mobile lab was donated to Oregon State University School of Chemical Engineering with testing and design conducted as a partnership. Covid-19 put this work on hold but planning continues with waste management infrastructure, local businesses and agricultural partners.

These trials will also produce financial guidelines for profitable deployment of this emerging technology internationally. Scalable infrastructure to profitably convert plastic into liquid fuel generates localized financial motivation to manage plastic waste as a valuable resource rather than a nuisance. Just as cash deposits have almost eliminated can and bottle debris, value for plastic scrap incentivizes plastic collection and recycling.

Direct Action

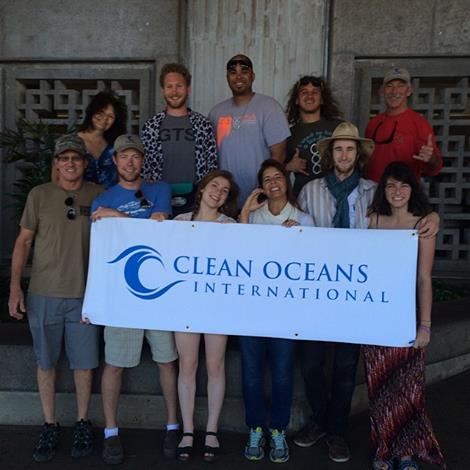

Direct action is where we apply what we have learned to solve specific problems. COI has had hundreds of volunteers join our expeditions and shoreline cleanup events. From 2013 to 2019 COI staff and volunteers collected debris and talked trash in Hawaii, Alaska, Brazil, British Virgin Islands, California, Canada, Florida, France, India, Malta, Oregon, Spain, and Switzerland. In these “Expeditions” we learned about variations in plastic packaging and local waste management practices and restrictions. In each location we visit, our waste management ideas are getting thoughtful consideration.

These tests and trials are an important prelude to deploying PPWC to isolated and remote locations. Deployed systems must be able to plug into cultural and demographic situations as seamlessly as the local grid to start up and operate effectively. Employment norms and regulatory considerations are essential for successful installations to operate. Our goal is to make PPWC available to any community at prices that motivate plastic management.

COI’s Research component is called "Environmental Plastic Assessment Program" (EPAP). EPAP works with volunteers conducting simple data collection on shorelines and during cleanup events, generating useful information with minimal financial input and creating awareness of plastic pollution through community networking and corporate team building.

Consistent shoreline and environmental monitoring must coincide with abatement measures to assess any changes positive or not. EPAP is simple enough to be done by 1-2 people using inexpensive hand tools.

Innovation

COI’s Innovation component is shrinking Portable Plastic Waste Conversion (PPWC) technology to convert plastic waste into diesel fuel and other products at any location.

Studies began using the Blest BeH, 1-Kg system and commercial chemistry analysis firms in 2010. Energy testing at COI began with the arrival of the initial EFT 100 PPWC system in 2015. In 2020, the COI PPWC mobile lab was donated to Oregon State University School of Chemical Engineering with testing and design conducted as a partnership. Covid-19 put this work on hold but planning continues with waste management infrastructure, local businesses and agricultural partners.

These trials will also produce financial guidelines for profitable deployment of this emerging technology internationally. Scalable infrastructure to profitably convert plastic into liquid fuel generates localized financial motivation to manage plastic waste as a valuable resource rather than a nuisance. Just as cash deposits have almost eliminated can and bottle debris, value for plastic scrap incentivizes plastic collection and recycling.

Direct Action

Direct action is where we apply what we have learned to solve specific problems. COI has had hundreds of volunteers join our expeditions and shoreline cleanup events. From 2013 to 2019 COI staff and volunteers collected debris and talked trash in Hawaii, Alaska, Brazil, British Virgin Islands, California, Canada, Florida, France, India, Malta, Oregon, Spain, and Switzerland. In these “Expeditions” we learned about variations in plastic packaging and local waste management practices and restrictions. In each location we visit, our waste management ideas are getting thoughtful consideration.

These tests and trials are an important prelude to deploying PPWC to isolated and remote locations. Deployed systems must be able to plug into cultural and demographic situations as seamlessly as the local grid to start up and operate effectively. Employment norms and regulatory considerations are essential for successful installations to operate. Our goal is to make PPWC available to any community at prices that motivate plastic management.